Time and Precision in Surface Modeling

As local SolidWorks design leaders, we often encounter a common question from our customers: "Modeling can't take long, right?" While efficiency is a priority for us, it's important to acknowledge that certain aspects of CAD modeling demand more time and attention, especially Surfacing and Tolerancing.

Surfacing

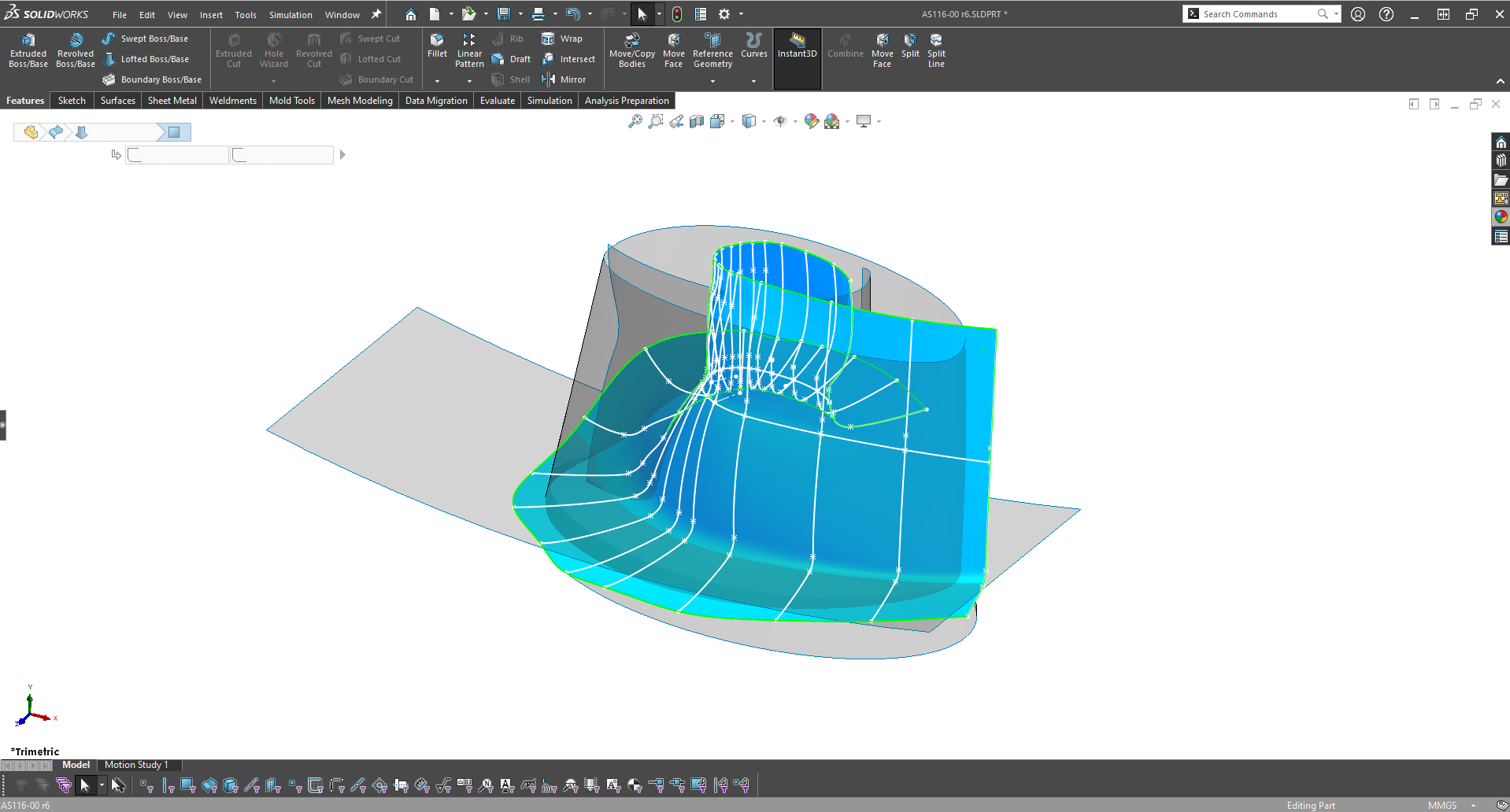

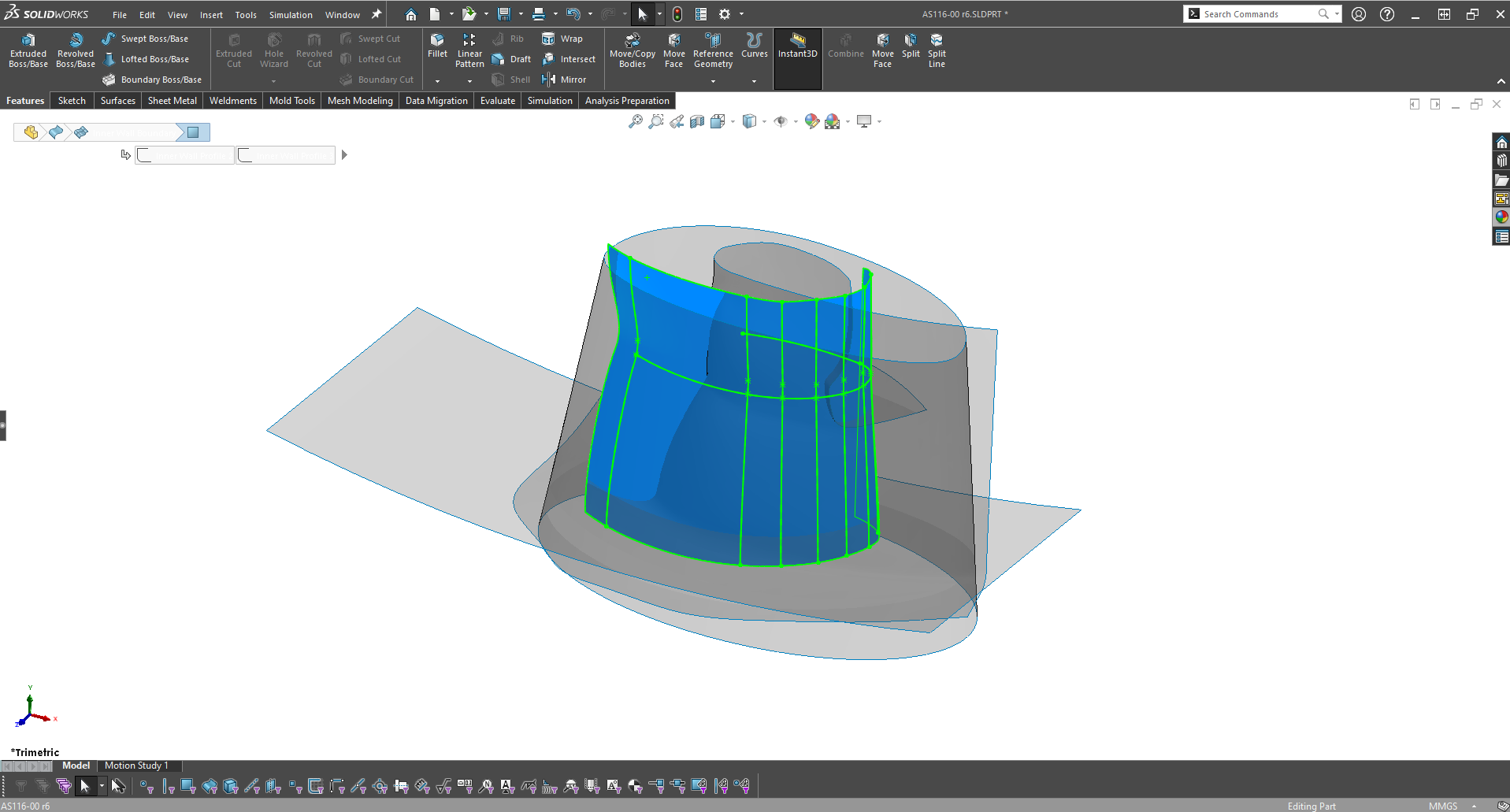

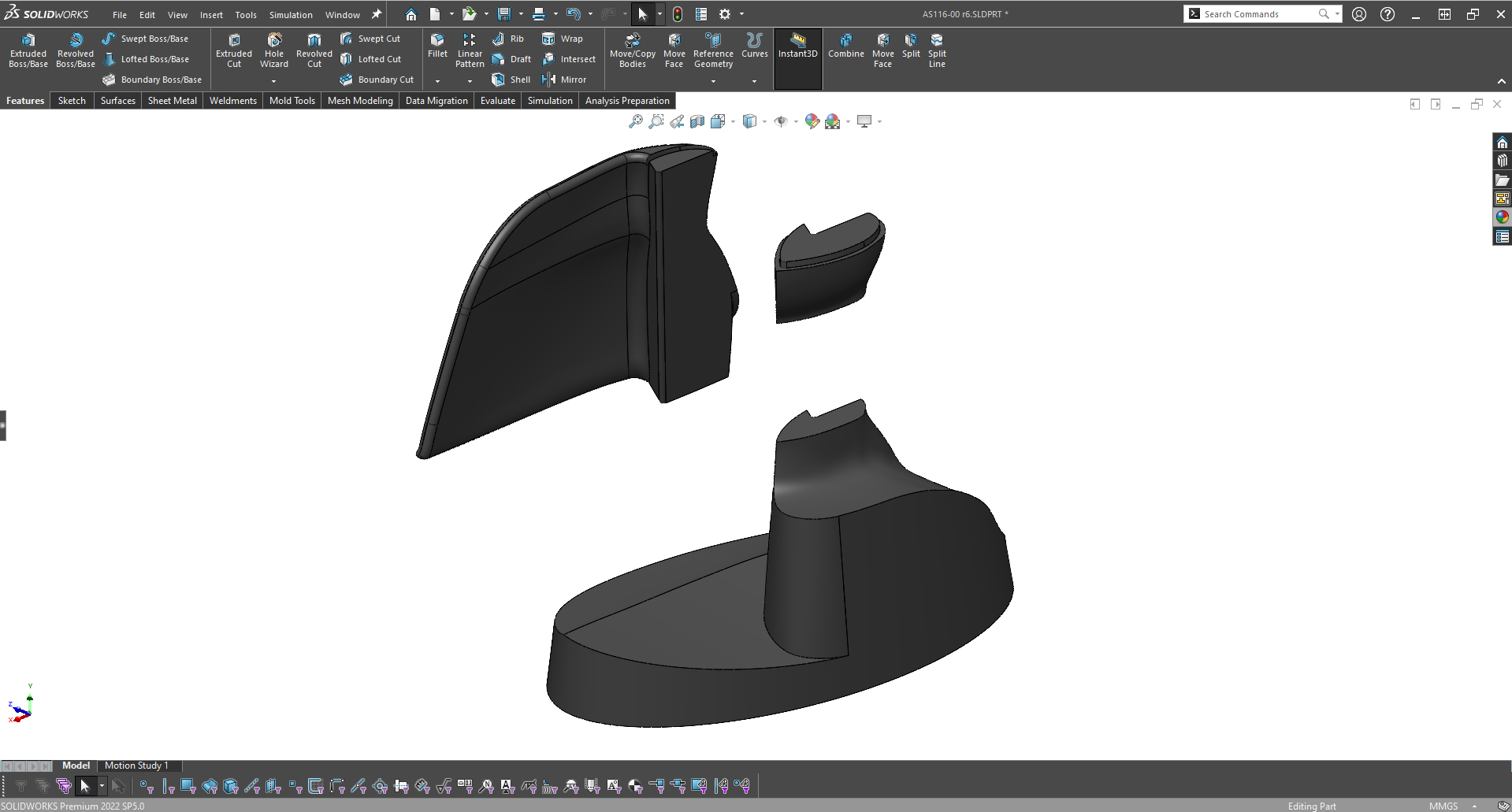

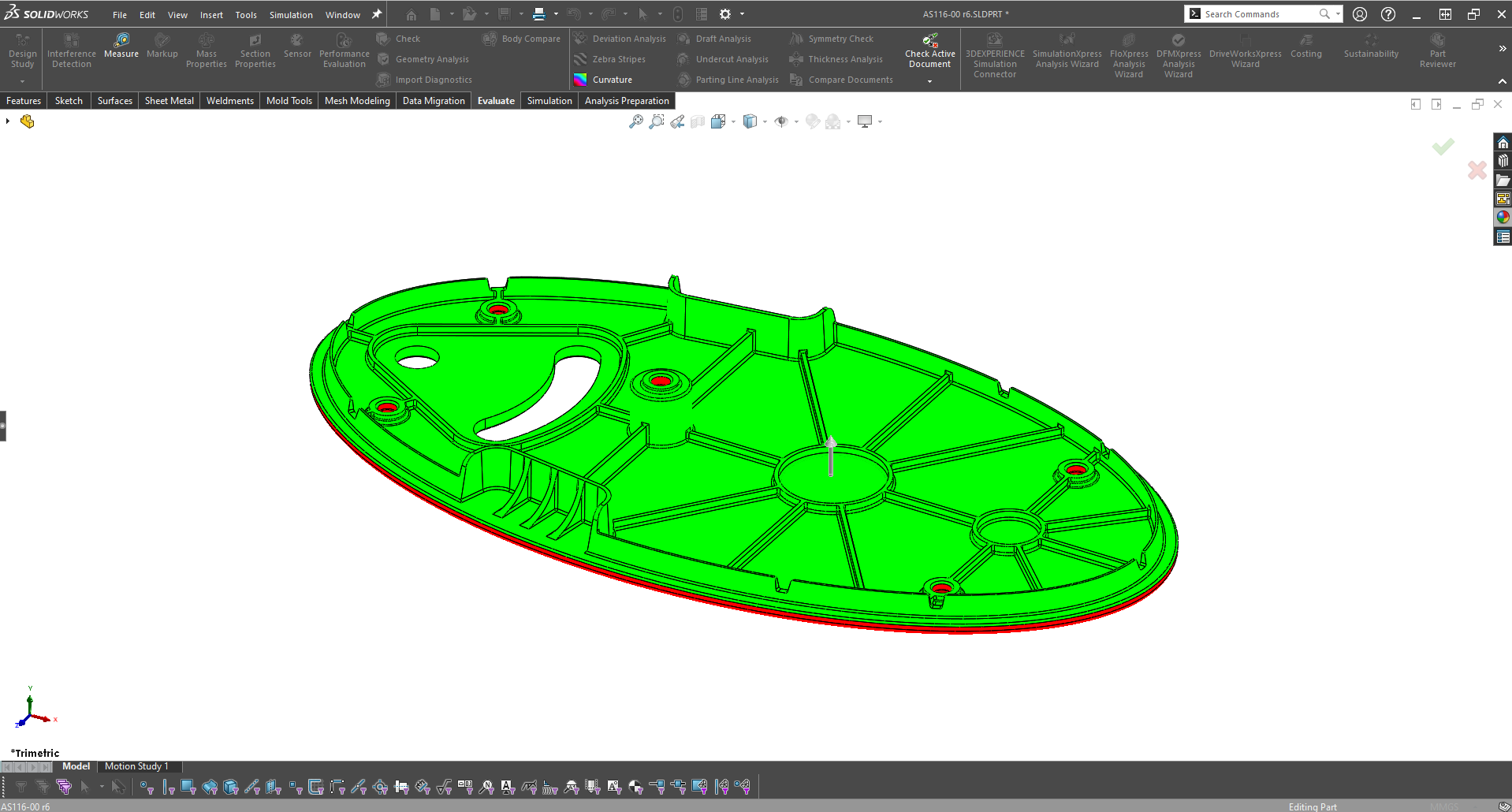

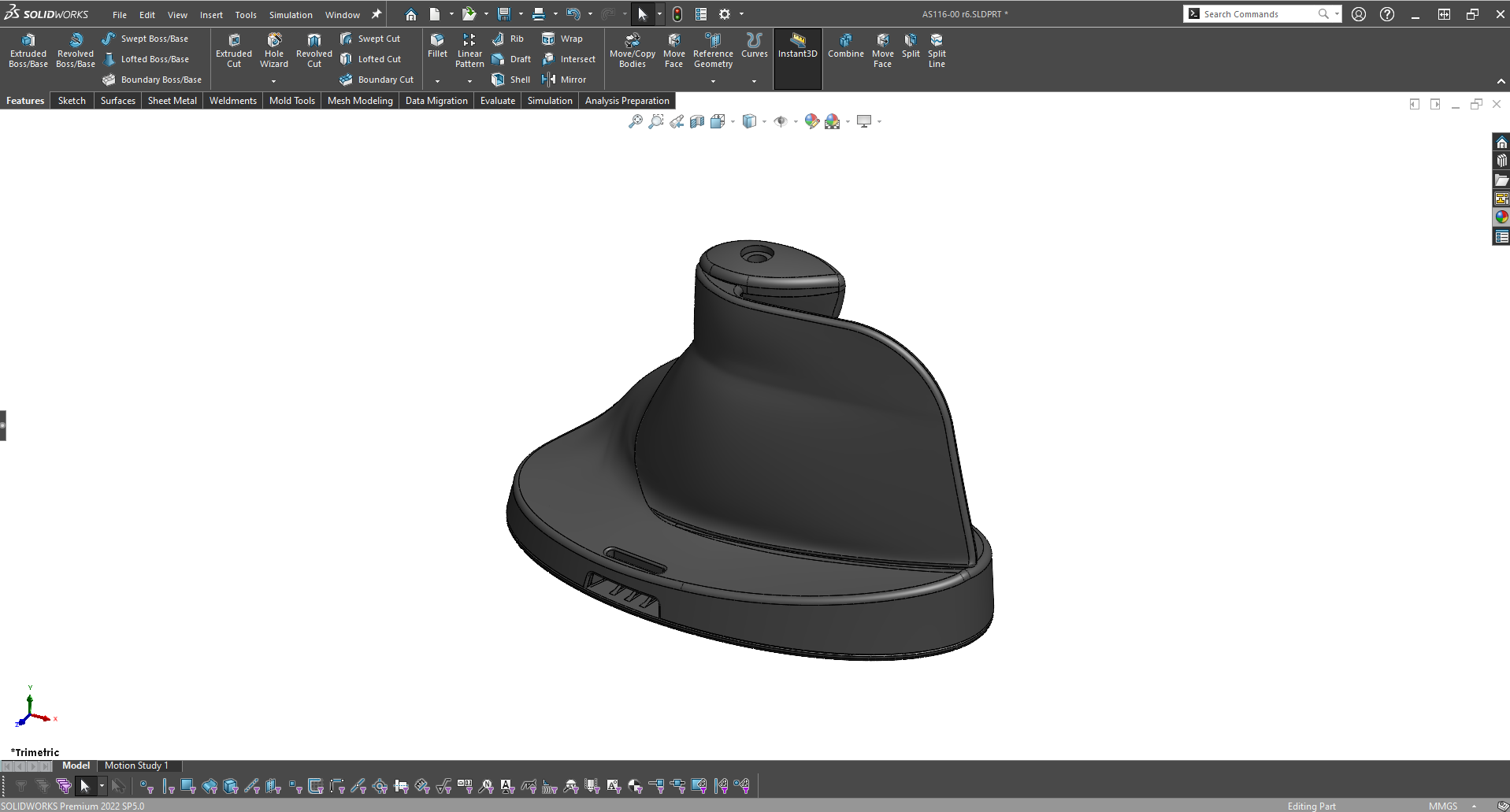

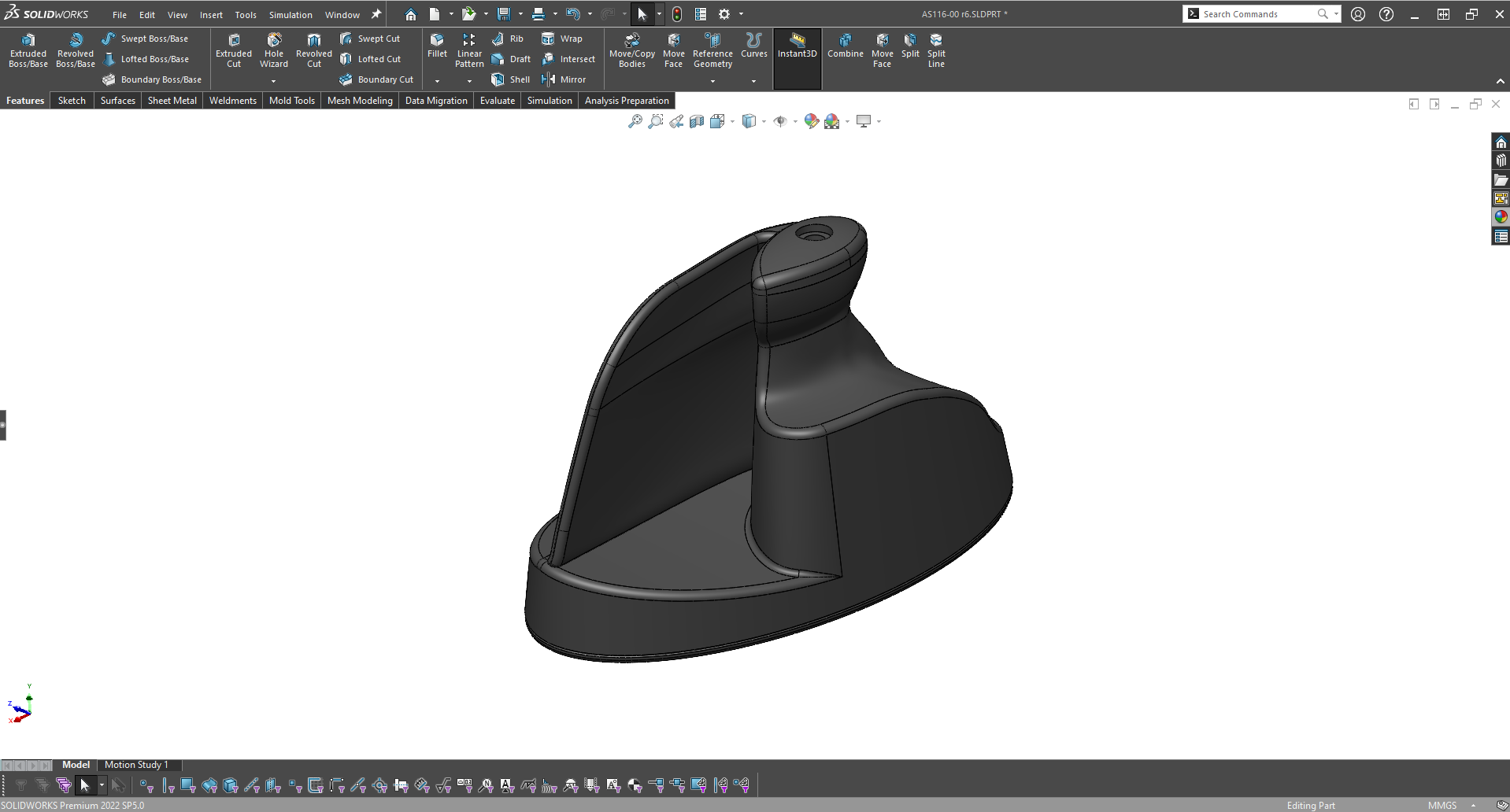

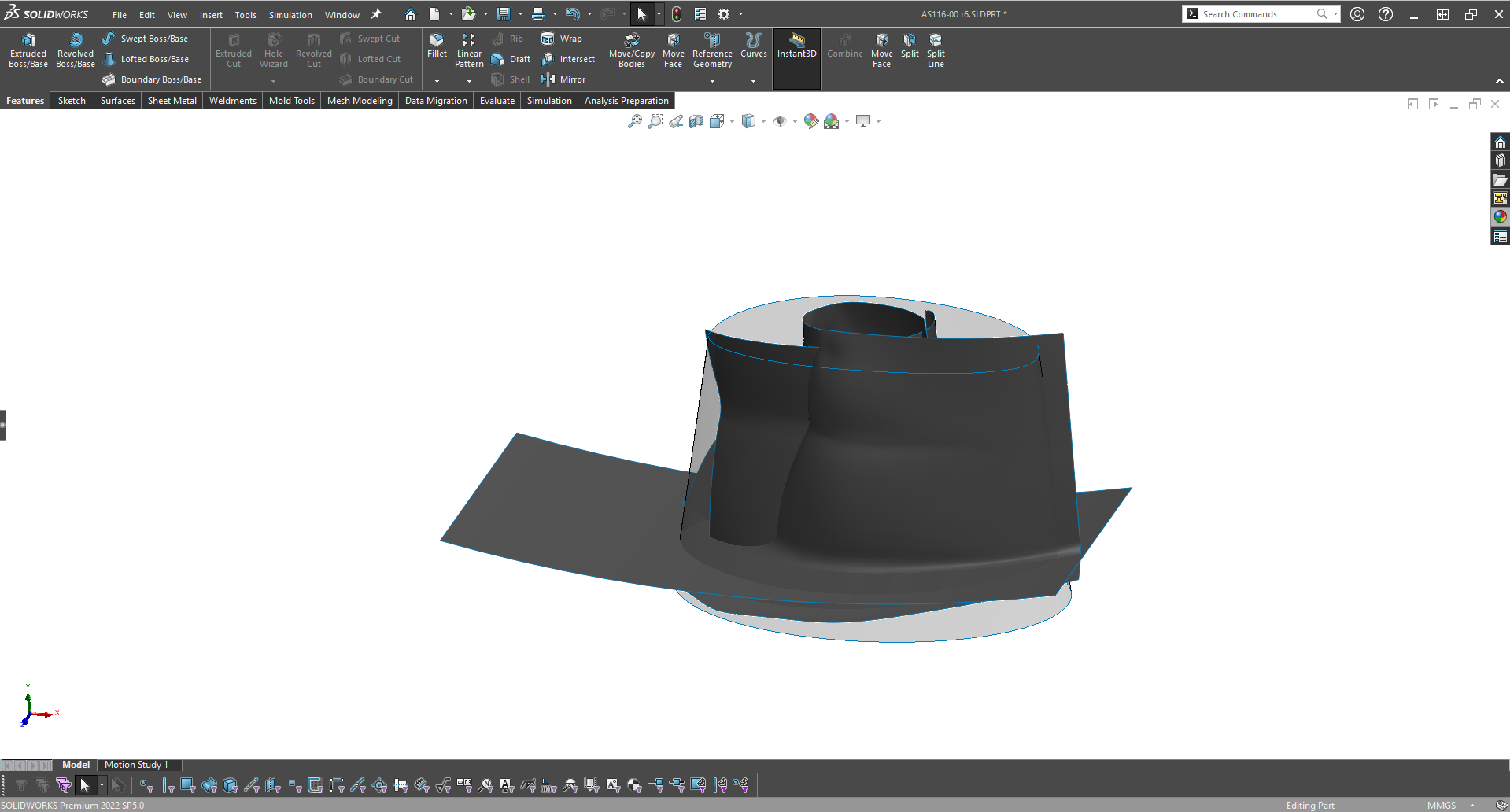

Commonly perceived as an advanced CAD technique, surfacing is the process of creating curved surfaces that are not solely determined by equations. While it may seem straightforward, dialing-in these surfaces to perfection can be a challenging task. For example, a flat or perfectly cylindrical model may require significantly less time to create than one with intricate or random curves. In our practice, we use SolidWorks Surfacing tools to navigate these challenges, and we are constantly seeking to improve our skills through platforms such as the SolidWorks User Group (SWUG). Also, with a certified SolidWorks Surfaces professional on our team, we ensure that our surfacing projects run as smoothly as possible. In addition, where a physical model is available, we use our 3D scanning services to speed up the modeling process, which is especially useful for designs that require intricate surfacing work.

Dialing-in Tolerances

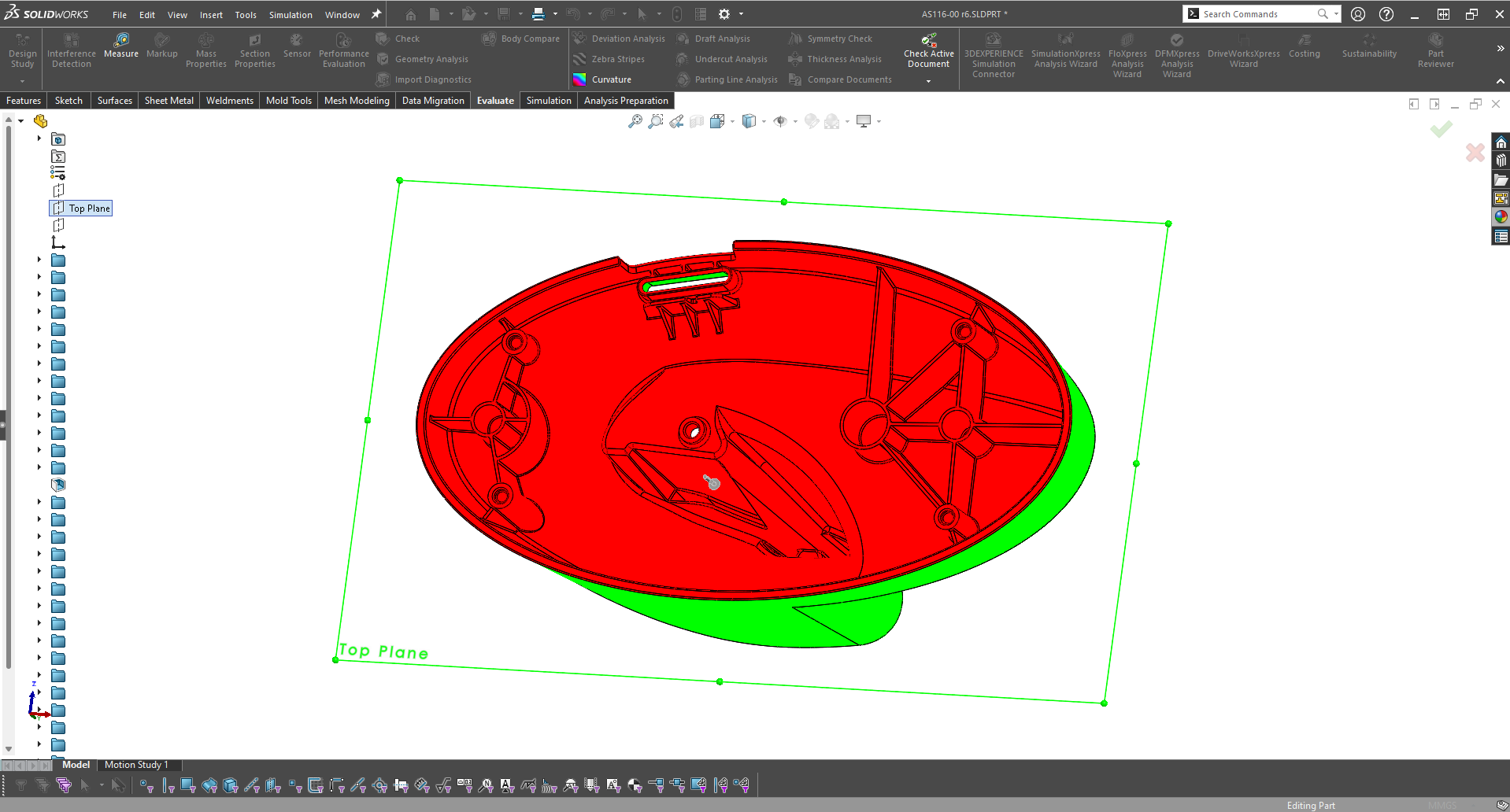

Designing something to a specific dimension might appear simple, but when considering manufacturing constraints or assembly requirements, achieving the desired dimensions often involves a process of trial and error. Tolerances play a crucial role in this process because real-world constraints might require changes to ensure the final product meets the intended specifications. For example, depending on the manufacturing method used, ideal dimensions may only be possible within a specific tolerance range, such as 1/32 inch. Even in 3D printing, temperature variations can have an impact on the final dimensions of a printed object. As professional designers, we must account for these factors and thoroughly review the math behind designed tolerances or prototypes. Investing more time in review or prototyping is invaluable in finalizing a design and lowering manufacturing costs in the long run.

Conclusion

In the dynamic world of CAD modeling, time and precision are intricately linked. While some aspects of modeling may require more time and effort, the investment pays off in the form of a finished product that functions properly and remains cost-effective during manufacturing. With accuracy and expertise, we navigate the challenges of surfacing and dialing-in tolerances to ensure that every design we develop meets the highest quality and craftsmanship standards. Our dedication to precision and efficiency set us apart as SolidWorks design experts, delivering exceptional solutions that exceed our clients' expectations and drive success in their goals.

Need Support?

If you find yourself in need of support or guidance in intricate modeling or designing for manufacturing, rest assured that we have you covered. Our team of professional designers is well-equipped to help you navigate the complexities of computer-aided design with modern tools and achieve your goals. If you're having trouble balancing time and precision in your designs, we can help. Schedule a meeting with one of our professional designers today to discuss your project needs and see how we can help you bring your vision to life. With our expertise and commitment to excellence, you can trust that you're in good hands every step of the way.

Our SolidWorks journey through curved realities demonstrates the intricate craft of recreating the real thing solely within the software, down to the subtle curves for a person's fingers to rest.